AS 9100 – Aerospace QMS

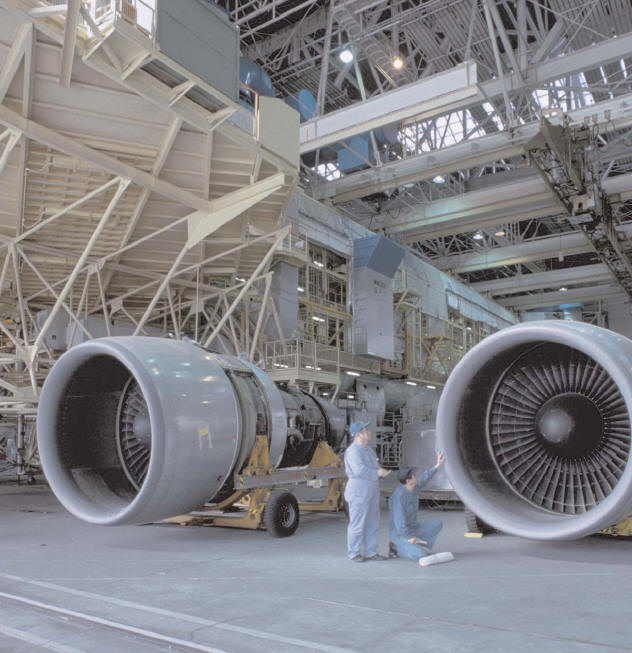

Quality and reliability are critical values for the aerospace industry. In such a complex industry, where mistakes and the failure of products and services can be fatal, the effective operation of a quality management system can help to reduce some of these concerns, and provide a framework for organizations to provide a product or service, which supports the values of quality and reliability.

The global aerospace industry has developed a number of standards to confront the issues of quality and reliability, and provide a framework for an effective quality management system. These standards have been embraced by the leading aerospace organizations, and their suppliers, and have gained recognition from a number of regulatory bodies around the globe.

AS 9100 series of standards are developed by the IAQG (International Aerospace Quality Group). The IAQG sets the standard for quality within the worldwide supply chain of the aerospace industry. IAQG comprised of member companies within the aviation, space and defense industries who design, develop, manufacture and support original equipment at system or subsystem levels. The IAQG is committed to establishing a commonality of quality systems and improvement standards. These standards are documented, published and applied internationally by original equipment manufacturers (OEMs) and circulated throughout the supply chain.

What is AS9100?

AS9100 is the aviation, space and defence version of a globally harmonized quality management system standard, based upon the internationally renowned ISO 9001 quality management system. It supplements ISO 9001, focusing upon the unique, complex, and highly regulated nature of the aerospace industry. Specifically, it emphasizes the critical aspects of key characteristics and the need to satisfy internal, governmental and regulatory requirements. The global nature of the standard allows commonality throughout the industry, allowing increased trade and co-operation.

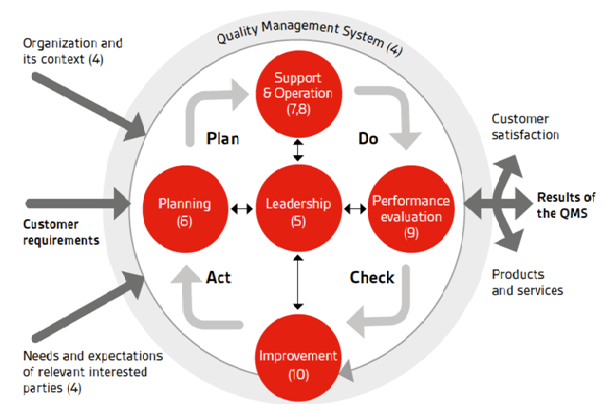

The standard, which is supported by the leading global aerospace organizations, is based around organizational processes. As with ISO 9001, the core concept is the Plan-Do-Check-Act cycle + Risk Based Thinking, which focuses the organization on its key processes. The model also builds in the ideas of planning, and reviewing, and that organizations should continually improve (see below).

The AS9110 quality management systems standard sets out the specific requirements that are critical for the maintenance of aerospace vehicles including commercial, private, and military. Like AS9100, it includes the ISO 9001 requirements, and supplements these with aerospace specific requirements. AS9110 is for MRO / CAMO companies that maintain and repair aerospace vehicles for the commercial or military sectors, or those that manufacture aircraft parts under FAA PMA regulations.

AS9120, is a further aerospace QMS specific standard that supplements ISO 9001. The focus of this standard is stockist distributors

Nucleus Consultants offers consulting, training and pre-auditing services to AS 9100, AS 9110, AS9120, as well the new standard AS 13100.

AS13100 AESQ Quality Management System Requirements for Aero Engine Design and Production Organizations Standard has been created to harmonize and simplify supplier quality requirements that are in addition to the requirements of AS 9100 Quality Management Systems – Requirements for Aviation, Space, and Defense Organizations and AS 9145 Advanced Product Quality Planning and Production Part Approval Process.

AS13100 sets out to create a common set of supplemental requirements with common reference materials to improve understanding, efficiency, and performance. While significantly simplifying the businesses of suppliers with multiple customers, the primary intent of this new standard is to improve overall product quality by focusing on the key systems and processes currently deterring consistent aerospace engine product quality.

Previously the Aerospace Engine Manufacturers based their supplier quality requirements on 9100 but had differing supplemental requirements and guidance albeit with largely the same intent. These supplemental requirements originate from the need to meet Regulatory, Customer, Industry, and Business requirements that are not explicitly covered by 9100 and 9145.

This standard sets out to create a common set of supplemental requirements with common reference materials to improve understanding, efficiency, and performance. While significantly simplifying the businesses of suppliers with multiple customers, the primary intent of this new standard is to improve overall product quality by focusing on the key systems and processes currently deterring consistent aerospace engine product quality.

These common supplemental requirements aim to raise the bar for anticipated performance in these key areas, and therefore detailed guidance is provided to ensure clarity of expectations.

This AS 13100 is not an 3rd party certifiable standard. This is self compliance standard and the Aero Engine customer may use this AS 13100 to audit their supply chain.

Nucleus Consultants offers consulting, training and pre-auditing services to AS 13100, AS 9145, AS 13002, AS 13003, AS 13004 and AS 13006.

Implementing the AS9100 series quality management system derives a number of benefits:

– Focuses the organization upon the key requirements of the customer

– Focuses the organization upon the key characteristics of aerospace products and services

– Demonstrates the operation of globally accepted quality standards

– Increased opportunities and acceptance within the global aerospace supply-chain

– Improved product and process quality

– Reassignment of supplier resources to quality improvement

– Potential reduction in variation of quality

– Efficiency gains

– Compliance with a system supported by regulatory bodies

– Potential reduction in 2nd party system audits

– Excellent levels of traceability throughout the supply chain

– Common language to improve understanding of quality requirements

Implementing AS 9100 series

Purchase the Standard

Before you can begin preparing for your QMS, you will require a copy of the standard. You should read this and make yourself familiar with it.

Review support information’s and documents

There are a wide range of quality support information’s and documents are available in internet to help you understand, implement and become certified to a quality management system. (You can watch our YouTube Channel for few information’s)

Form a core team and agree on your strategy

You should begin the entire implementation process by preparing your organizational strategy with top management. Responsibility for a QMS lies with Top Management, therefore it is vital that Top Management is involved from the beginning of the process. With the support of Top Management form a core team. This team can include the process owners, members.

Consider Training

Whether you are the Quality Manager or a Process Owner seeking to implement a quality management system or a Senior Manager who would like to increase your general awareness of AS 9100 series, and aerospace and defence industry specific topic like Prevention of counterfeit parts, FOD, Product Safety, Configuration Management, AAM, ITAR/EAR etc. There are a range of workshops, seminars and training courses available.

Review Consultancy Options

The consultancy is the 3rd party like NUCLEUS, You can receive advice from independent consultants on how best to implement your quality management system. They will have the experience in implementing a QMS and can ensure you avoid costly mistakes.

Choose a register

The registrar is the 3rd party, like (Check with IAQG website for the accredited certification body) who come and assess the effectiveness of your quality management system, and issue a certificate if it meets the requirements of the standard. Choosing a registrar can be a complex issue as there are so many operating in the market. Factors to consider include industry experience, geographic coverage, price and service level offered. The key is to find the registrar who can best meet your requirements. A great place to start is by contacting us.

Develop a Quality Management System

You need to establish, implement, maintain and continually improve a Quality Management System in line with AS 9100 / AS 9110 / AS 9120. Your processes need to adhere the Plan-Do-Check-Act + Risk Based Thinking.

Develop support documentation

QMS Documentation outlines your intention to operate in a systemic manner. It outlines why you are in business, what your intentions are, how you are applying the standard and how your business operates. This is incudes processes, procedures and other documented. Quite simply, it outlines what you do to complete a task. It describes who does what, in what order and to what standard.

This is typically a procedures manual that supports the Quality manual. Quite simply, it outlines what you do to complete a task. It describes who does what, in what order and to what standard.

Implement your Quality Management System

The key to implementation is communication and training. During the implementation phase everyone operates to the procedures and collects records that demonstrate you are doing what you say you are doing.

Conduct Internal Audit and Management Review

At planned intervals you need to conduct an internal audit and a management review to verify the established QMS is confirming the applicable requirements and it is effective, suitable and adequate

Gain registration

You should arrange your initial assessment with your registrar. At this point the registrar will review your QMS and determine whether you should be recommended for registration.

Continual assessment

Once you have received registration and been awarded your certificate, you can begin to advertise your success and promote your business. To maintain your registration, all you need to do is continue to use your quality system. This will be periodically checked by your registrar to ensure that your Quality System continues to meet the requirements of the standard.

QMS Registration

Registration to AS 9100 / AS 9110 / AS 9120 takes place when an accredited 3rd party visits an organization, assesses the management system and issues a certificate to show that the organization abides by to the principles set out in AS 9100 / AS 9110 / AS 9120.

Your Quality Management Systems certificate is a sign of acceptability which saves you having to prove your quality standards to discriminating customers. AS 9100 / AS 9110 / AS 9120speaks an international language. Once you are certified means, the certificate is valid for 3 years and it is subject to the completion of the annual surveillance audit.

Why do I need registration?

Gaining registration to AS 9100 / AS 9110 / AS 9120 through various certification bodies will help your organization flourish. Whether you are looking to operate internationally or to expand locally to accommodate new business, AS 9100 / AS 9110 / AS 9120 will help you demonstrate to customers that you have a commitment to quality.

The regular assessment process will ensure you continually use, monitor and improve your processes.

Registration can improve overall performance, remove uncertainty and widen market opportunities.

To know more about AS 9100 / AS 9110 / AS 9120 / AS 13100 / AS 9145 and Aerospace and Defence Industry Specific Training and Consultancy Services please contact us on +91 9600001996 and mail to info@nucleus-india.com